Health debate: Sugar beet vs sugar cane—what should you choose?

The Value of Sugar Beet Vs Sugar Cane: a Closer Check Out Their Manufacturing Processes and Applications

The value of sugar beet and sugar cane prolongs beyond their duty as sources of sucrose. Each plant features distinct manufacturing procedures that affect their applications throughout numerous sectors. While sugar beet supports not simply food manufacturing yet additionally biofuels and fertilizers, sugar cane primarily serves the food sector with beneficial results. Understanding these distinctions reveals how each crop forms farming economic situations and sector techniques globally, motivating more expedition into their one-of-a-kind payments.

Summary of Sugar Beet and Sugar Cane

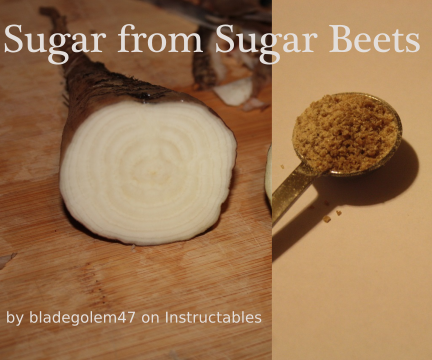

Sugar beet and sugar cane are two main sources of sucrose, each with distinct features and growing techniques. Sugar beet, an origin vegetable, grows in temperate climates - Sugar beet vs sugar cane. It is cultivated largely in the Northern Hemisphere and calls for well-drained dirt. The plant typically expands to an elevation of concerning 18 inches, with a white, fleshy root including about 15-20% sucrose. On the other hand, sugar cane is a tropical lawn that prospers in warm, damp problems. It can reach elevations of as much as 12 feet and is composed of high, jointed stems that shop sucrose concentrations varying from 10-15%. The growing of sugar cane is labor-intensive and typically entails manual harvesting. Both plants act as necessary farming assets, giving basic materials for sugar manufacturing and different by-products. Their farming methods considerably influence local economies and worldwide sugar markets, making them essential to the farming landscape

Harvesting Techniques for Sugar Beet and Sugar Cane

Collecting strategies for sugar beet and sugar cane vary markedly as a result of the distinct qualities of each plant. Sugar beet collecting usually employs customized machinery called beet harvesters, which effectively uproot the beets from the soil while decreasing damage. These machines utilize a collection of blades to cut the tops and raise the roots, making certain that the beets stay undamaged for processing.In contrast, sugar cane harvesting usually entails 2 key approaches: hand-operated cutting and mechanical harvesting. Manual harvesting, still prevalent in some regions, needs workers to reduce the cane stalks by hand utilizing machetes. This technique permits discerning harvesting but is labor-intensive. Mechanical harvesters have obtained popularity, employing revolving blades to cut and gather the stalks swiftly. Both approaches intend to enhance yield and quality, with mechanical harvesting progressively taken on to satisfy rising manufacturing needs effectively.

Handling Techniques for Sugar Beet

After being collected, sugar beetroots undergo a series of processing steps to extract sucrose efficiently. The primary step entails cleaning the beets to remove soil and pollutants. Next, the beetroots are sliced right into slim strips known as cossettes, which raises the surface location for removal. These cossettes are after that subjected to warm water extraction in a diffusion procedure, permitting sucrose to liquify right into the water.Following removal, the juice includes impurities and is clarified utilizing lime and warmth to precipitate solids. The made clear juice is after that concentrated via evaporation, removing excess water and enhancing sugar focus. To crystallize the sucrose, the focused juice goes through further dissipation and cooling, developing sugar crystals. Ultimately, these crystals are separated from the continuing to be syrup with centrifugation, dried, and packaged for circulation. This technique guarantees a high return of sucrose while preserving the high quality of the last product.

Processing Methods for Sugar Cane

Handling sugar cane involves a series of steps made to extract sucrose successfully. The procedure starts with harvesting, where mature sugar cane is reduced and transferred to processing centers. As soon as at the mill, the cane goes through washing to get rid of contaminations. The following step is crushing, where mechanical rollers essence juice from the coarse stalks.This juice is after that made clear utilizing warmth and lime to get rid of suspended solids and pollutants. Adhering to clarification, the juice is vaporized to focus the sugar content, causing a thick syrup. The syrup undergoes crystallization, where sugar crystals create as the syrup cools down. These crystals are divided from the continuing to be molasses with centrifugation.Finally, the sugar is dried and packaged for distribution. This detailed processing method warranties that sugar cane yields a high-grade product, ideal for numerous cooking and industrial applications, while taking full advantage of the extraction of sucrose from the raw material.

Nutritional Distinctions In Between Sugar Beet and Sugar Cane

The contrast in between sugar beet and sugar cane expands past their handling approaches to include significant dietary distinctions. Sugar beet has not just sucrose however additionally a range of nutrients, including vitamin C, potassium, and magnesium. These nutrients add to its possible health and wellness advantages, such as sustaining immune function and preserving electrolyte equilibrium. In comparison, sugar cane generally gives sucrose with marginal levels of necessary nutrients.Additionally, sugar beet has a higher fiber material, which can aid in digestion and promote satiety. The existence of antioxidants in sugar beet may additionally provide protective effects against oxidative tension, an element linked to different chronic illness. While both sources are mostly used for sugar manufacturing, the dietary profiles suggest that sugar beet may use added health and wellness benefits contrasted to sugar cane. This difference is critical for consumers seeking more than just sugar in their diet plans.

Applications of Sugar Beet in Numerous Industries

A range of industries leverage sugar beet for its flexible applications past sugar production. In the food industry, sugar beet functions as a key ingredient in producing different investigate this site processed foods, consisting of sugary foods and baked goods, because of its natural sweetness. Additionally, the pulp originated from sugar beet is utilized as pet feed, offering a nutrient-rich source for livestock.In the biofuel field, sugar beet is progressively recognized for its possibility in creating bioethanol, adding to sustainable energy services. The farming market take advantage of sugar beet's results, which can be used as organic plant foods, improving soil health and wellness and fertility.Furthermore, sugar beet essences are utilized in pharmaceuticals and cosmetics, where they function as all-natural sweeteners and humectants. These varied applications highlight sugar beet's function as a valuable resource in boosting sustainability and innovation throughout numerous markets, strengthening its significance in contemporary manufacturing methods.

Applications of Sugar Cane in Various Industries

Regularly Asked Questions

What Environmental Impacts Are Connected With Sugar Beet and Sugar Cane Production?

The ecological influences of sugar beet and sugar cane manufacturing include soil degradation, water usage, chemical application, and habitat disturbance. These variables add to ecological inequalities, increasing problems concerning sustainability in agricultural techniques related to both crops.

How Do Sugar Beet and Sugar Cane Compare in Terms of Economic Viability?

The financial practicality of sugar beet and sugar cane differs based on factors like geographic area, production prices, and market demand - Sugar beet vs sugar cane. Both Click This Link crops supply distinct benefits, influencing farmers' choices relating to farming and financial investment in different regions

What Are the Key Regions for Sugar Beet and Sugar Cane Growing?

Just How Does Climate Influence the Growth of Sugar Beet and Sugar Cane?

Climate significantly influences the development of sugar beet and sugar cane. Sugar beets flourish in cooler temperatures, while sugar cane requires warm, tropical problems. Sugar beet vs sugar cane. Both plants depend on sufficient rainfall and sunlight for optimal growth and return

Exist Any Kind Of Significant Health Issues Connected to Consuming Sugar From These Resources?

Wellness problems associated to sugar intake consist of weight problems, diabetes, and heart disease. Both sugar beet and sugar cane-derived sugars can add to these issues, especially when eaten in too much amounts, despite visit this site their resource.